All Vetter small conveyors (with the exception of FR-12-20) are equipped with state-of-the-art Faulhaber EC motors (brushless DC motors) with integrated speed controller.

Interference contours? No, thanks! Along with the gear motors, the control electronics are integrated in the housing of the small conveyors in the typical “Vetter” fashion.

Service made easy: The new generation of motors is mechanically fully compatible with the brushed motors which have been in use for more than 20 years now. Replacement is considerably simplified as a result of the electrical plug connectors.

The small conveyor can also be operated cyclically using the analogue signal. If you additionally use programmed acceleration and deceleration ramps in your controller, this is easy on the mechanical system. Thanks to brushless technology, it is possible to achieve high acceleration currents without causing motor wear.

The speed controllers integrated in the motor have a signal input for specifying the direction of rotation, which makes it easy to change the conveying direction.

The signal output provides you with 32 pulses per motor shaft rotation for processing in your controller. This makes it possible to implement positioning tasks without additional encoders. We would be happy to help you calculate the resolution.

Apply voltage – done!

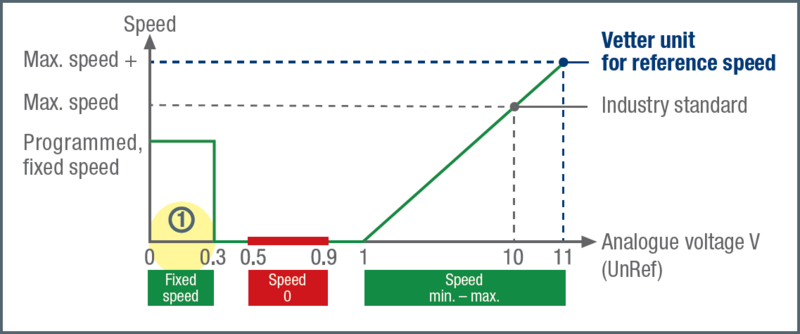

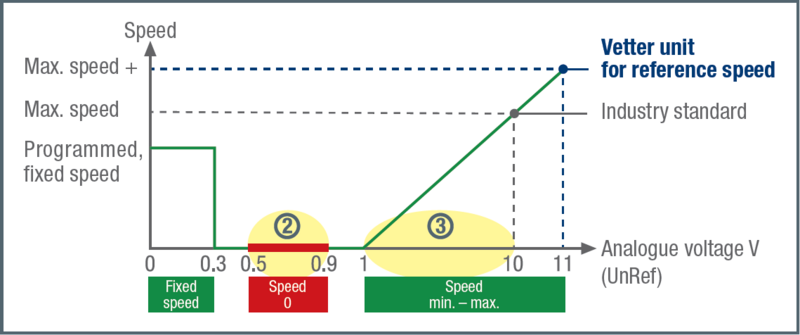

Your Vetter small conveyor can be operated in the simplest mode. All you need is a 24 V DC supply voltage. The direction of rotation input is connected to 24 V DC or 0 V CD (GND), which determines the conveying direction. The analogue input is connected to 0 V DC (GND) and the small conveyor starts with the factory-programmed speed (refer to 1).

Reference speed via analogue signal (0 – 10 V DC)

If you want to vary the speed, simply provide a corresponding signal at the analogue input: the conveyor is motionless in the range from 0.5 to 0.9 V DC (refer to 2). From 1 to 10 V DC, the full rotational speed range of the motor is available (refer to 3).

With a Vetter setpoint device, you are provided with approx. 110 % of the specified nominal speed from 10 to 11 V DC.

To ensure that your conveyed goods always arrive at their destination at the right time, our range includes suitable electronic setpoint devices for our small conveyors.

The setpoint devices are installed upstream of the drive of the corresponding conveyor and are easy to operate manually or can be electronically controlled via one of your system’s existing controllers. This way, you individually determine the conveying speed of your conveyed goods to suit your requirements.